Forced Vibration in Machine Foundation

Different Types of Machine Foundations and their Uses

Heavy machine foundations are a special kind of foundation needed for machines, machine tools and heavy equipment that have a wide range of speeds, loads and operating conditions. These bases have been considered to result in shock and vibration as a result of the operation of the machines.

Following are the types of machine foundations generally used:

Lead Structural Ltd. Works and Construction Limited specializes in heavy plant machinery bases, which provide the foundation for all industrial applications. Working together with the brief and technical specifications of each client, we build strong and durable foundations to meet manufacturing needs.

Lead Structural Ltd. Works have the experience needed to provide a complete set of foundations for a large factory, including a factory car park and dock loader. We can also provide expert foundations for key pieces of machinery, including weight bridges, lathes, pit conveyors and crane pads.

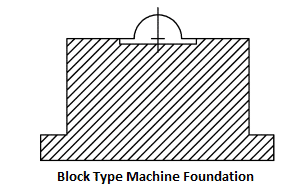

1. Block Type Machine Foundation:

The following figure shows the Block Type Machine Foundation. This type of foundation consists of a pedestal rest that is large in length and the natural frequency is small.

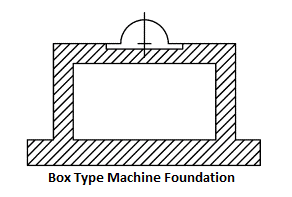

2. Box or Caisson Type Machine Foundation:

The Box Type Foundation consists of a hollow concrete block, as shown below. The bulk of this foundation is less than the Block Type Machine Foundation because it is hollow. The natural frequency of the Box Type Machine Foundation has increased.

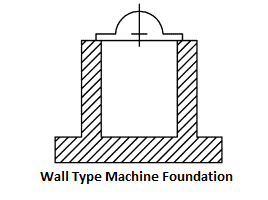

3. Wall Type Machine Foundation:

This type of machine foundation consists of a pair of walls on which the slab is left. This type of foundation is made of the same material. It is used for smaller machines and the machine is rested on the upper slab.

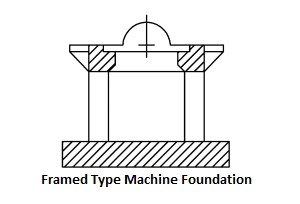

4. Framed Type Machine Foundation:

This type of machine foundation consists of vertical columns with horizontal frames on their tops. It is used for large machines. Machines are placed on top of frames. The vertical and horizontal members of this foundation can be constructed through various materials.

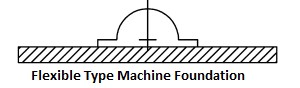

5. Non-Rigid or Flexible type of Machine Foundation:

Following figure shows the non-rigid or flexible foundation.

The following general requirements of the machine foundation will be satisfied and results will be checked before the foundation details.

Accuracy, precision and proper application is paramount to delivering machinery foundations for industrial use:

At Lead Structural Ltd., we understand that for anyone who wants to install new machinery on their premises. Once you have selected the required equipment, please contact us and we can take it from there. As long as you have the drawings of the machine manufacturers, we will work with them and offer a complete service for pricing, design and building foundations.

We Are Used To Heavy Industry

Lead Structural Ltd. was originally created over 35 years ago to serve the steel industry, giving us a unique understanding of the heavy industry and, most importantly, safe in and around such dangerous environments. How to work Health and Safety We are at the forefront of any project that we produce with the risk assessment and methodology statements developed for each project. Since we started in several fields, please take a look at the extensive list of industries we have worked in and recent projects that we have started.

Some of the machines we have installed in the past:

- Press foundations

- Hammer foundations

- Chimney Foundations

- Industrial Printer Foundations

- Can making foundations

- Milling Machine Foundations

- Corrugator Foundations

- Industrial Knife Foundations

- CNC Machines

- Crane Foundations

- Steel Ladle Foundations

- Industrial Generator Foundations

Heavy Machinery Foundations are our specialty

We have the ability to provide reliable foundations for everything from confluence pit to complex multi-level machinery setup. We appreciate that, in any industry, safety comes first, which is why all procedures and structures are supported by risk assessment and RAMs.

Heavy Machinery Is Our Speciality

Our projects section speaks for itself and as one of the UK leaders we set up hundreds of heavy machine foundations. Trust us when we say, no wonder! We have a wide range of expertise, just check out your projects section or watch a short summary on the video for some Lead Structural Ltd. construction projects.

If you are planning to incorporate heavy machinery into an industrial facility, it is important to make sure your foundations provide specific support.

Large Factory & Specialist Machinery Foundations

Weigh Bridge Construction

At Lead Structural Ltd. Works, we have the experience needed to provide the necessary infrastructure for an efficient wage bridge station. We understand the importance of these important stations in the factory setting and provide professional service accordingly

Foundation & Concrete Bases

Whatever the concrete needs, we have the experience and expertise in all aspects of the foundation and concrete bases and we can meet all the requirements

Expertise Gained over 30 years

Lead Structural Ltd. has more than 45 years of expertise and experience in the industry and can offer advice and guidance to help clients and specifiers understand what to expect from concrete floors and foundations.

We provide a complete engineer solution that is fully compatible with all site conditions and all foundations and base piling systems.

Our concrete and foundation services include the designation of steel frames, bolts for elevator pits and walls, piles and pavement beams. We have experience and expertise in all aspects of foundation and concrete bases and we can meet all of its requirements. Part of a project.

We provide thorough training on steel fixing and set up staff to perform membranes, formwork and reinforcements prior to the site’s arrival. This can be checked even before laying eggs where high quality and attention to detail can be maintained.

Our range of expertise includes but is not limited to:

- Ground Bearing Floors

- Concrete to metal decking

- Suspended Ground Floors

- Concrete screeds to pre-cast beams

- Concrete to overlays to existing floors

- Concrete to roads and hard standings

- Power Float finishing

- Brush finished bays

- Farm Yards

- Stables

- Concrete to basements

- Machine Foundations

General Requirements of Machine Foundations during Design and Detailing:

Free vibrations occur without any external forces and are influenced by forces within the system itself. But there is no external force or natural disturbance needed to initiate free vibration. There are two types of free vibrations.

- Damped vibrations

- Undamped vibrations

The following general requirements of machine foundations shall be satisfied and results checked prior to detailing the foundations.

- Settlements must be within valid limits.

- The combined centre of gravity of the machine and the foundation, as far as possible, should be in the same vertical line as the centre of gravity of the base aircraft.

- There should be no resonance, so the natural frequency of the foundation soil system must be either too large or too small compared to the machine’s operating frequency. For low-speed machines, the natural frequency should be higher.

- According to the Terms of Service, the dimensions should be within the valid limits that have been set by the machine manufacturers.

- All rotating and rotating parts of a machine must be well-balanced so that unobtrusive forces or moments can be minimized.

- Wherever possible, the Foundation should be planned in such a way that the base area or mass is altered to allow for natural frequency reduction later.

From the practical point of view, the following requirements should be fulfilled

- The groundwater table should be as low as possible and the ground surface level as deep as at least one-quarter of the width of the foundation below the base plane. It limits the spread of vibration, groundwater is a good conductor of vibration waves.

- The foundations of the machine should be separated from adjacent building components by extension joints.

- Any steam or hot air pipes embedded in the foundation should be properly isolated.

- The foundation should protect the machine oil from the acid-resistant coating or by appropriate chemical treatment.

- The machine foundation should be taken below the ground level of adjacent buildings.

Vibration Analysis of Machine Foundations

The machine foundation carries a dynamic load. These loads produce vibration movements that extend into the soil beneath the foundation. The impact of these vibrations on the soil is analyzed using the kinetics of soil dynamics and the theory of vibration.

Types of Vibrations in Machine Foundation

There are two types of vibrations in machine foundation:

- Free vibration

- Forced vibration

Free Vibration in Machine Foundation

Forced vibration is accompanied by constant external forces on the machine foundation. We say that a moist air system is subject to the exciting force F (t). Can be written as the equation of motion.

Vibration Analysis of Machine Foundation

General Requirements of Machine Foundations during Design and Detailing:

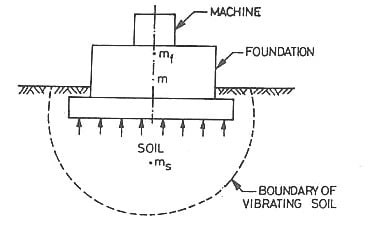

To analyze the vibration theory of the machine foundation, we need to assume that the machine foundation has some degree of freedom. Usually the machine foundation has 6 degrees of freedom.

We say that the machine foundation remains on a large scale soil. Now the machine and the foundation work together on a large scale and it is the MF that works at the center of the system’s gravity. The mass of soil that works upwards is called MS. The elastic action of the soil is strongly dependent on the vibration of the system. Movement resistance dependence damping coeype c.

Therefore, these three large-scale, hardness and damping coefficients are needed to complete the machine foundation analysis. The parameters described above are described below.

Mass (m):

Whenever the machine vibrates, the soil beneath the machine foundation also vibrates. The mass of the clay that causes the vibration is called the mass of the clay. Therefore, the total is equal to the mass (m)

m = mf + ms

Where,

mf = mass of the foundation

ms = in-phase soil mass = it varies from 0 to mf

Total mass (m) varies from mf to 2mf.

Laboratory Method of Vibration Analysis:

In the laboratory, a triangular test with vertical vibration is performed and the rigidity modules are obtained. The modulus of this young is determined by the Poisson ratio.

Young’s modulus E = 2G(1+u)

Stiffness k = AE/L

Where E = young’s modulus

G = rigidity modulus

U = positions ratio

Barkan’s Method:

Hardness can also be obtained from Barkan’s suggested formula given below.

Where A = area of contact

Plate Load Test:

A plate load test is performed in the field and determines soil hardness as the slope of the load accuracy curve.

For cohesive soils, Stiffness K

For cohesionless soils, Stiffness k

Where,

B = width of foundation

Bp = diameter of plate

Resonance Test:

By knowing the resonant frequency (FN), we can calculate the cost of hardening. The fn can be determined by placing a mass meter vibrator on the ground-mounted steel plate.

Therefore, stiffness

Damping Constant (c)

When the vibration energy is exhausted from the soil, it becomes moist. The main causes of moisture preparation are viscous effects and loss of internal friction due to hysteresis, radiation loss due to diffusion of waves through the soil.

The damping constant is obtained from the area of the hysteresis loop of the load-deformation curve as follows.

Where,

work lost in hysteresis

W = total work done.

The damping constant varies from 0.01 to 0.1